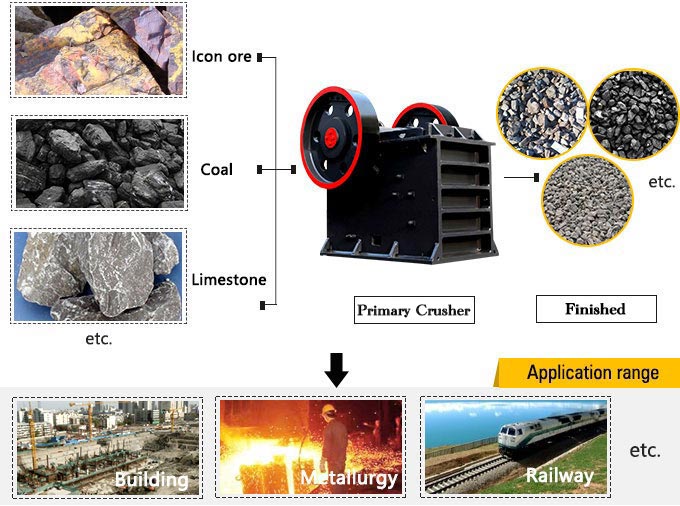

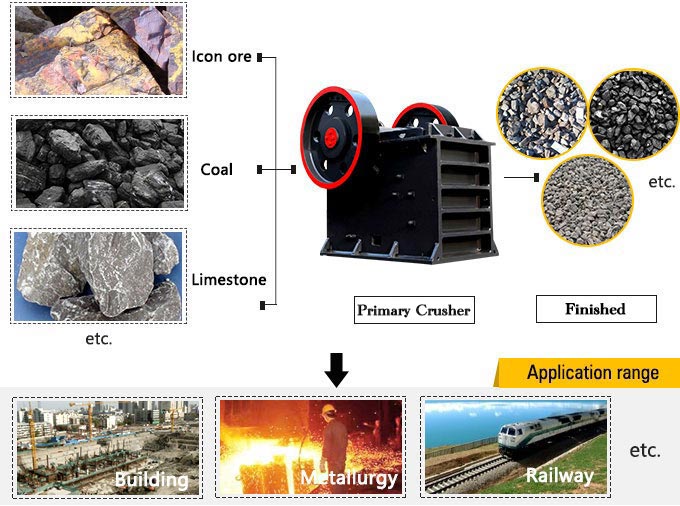

The Application and Function of Primary Crusher:

Primary crusehr can be widely applied in mining, metallurgy, architecture, highway, railway, water conservation, chemical industry and other industries, for different ores and big materials medium crushing.

Primary crusher is suitable for:

1. Both stationary and mobile process

2. Surface and underground applications

3. Mining companies, major quarries

4. Medium and large scale contractors

The Working Process of Primary Crusher:

Through the motor wheels, the eccentric shaft is driven by the triangle belt and slot wheel,which make the movable jaw plate keeps moving by a regulated track. Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and cheek plate can be crushed and discharged through the discharging opening.

1. It adopts world-level manufacturing technology and high-end manufacturing materials.

2. More advanced movable jaw assembly makes it more durable. The movable jaw assembly uses high-quality steel casting and drives through two large-sized cast steel flywheels. In addition, the heavy eccentric shaft also adopts forging stock which makes JC series jaw crusher have extraordinary reliability.

3. The bearing pedestal adopts unitary cast steel structure. The unitary cast steel bearing pedestal can ensure comprehensive fitting with the crusher rack, and at the same time, greatly increase the radial strength of the bearing pedestal, whereas split type bearing pedestal does not have these advantages.

The working manner of this series crushing machine is dynamic extrusion type, and its working principle goes like this: the electro motor drives the belt and belt wheel to make the movable jaw to move up and down through the eccentric shaft, and then movable jaw goes up, the angle between the toggle pate and the movable jaw is bigger, thus pushing the movable jaw to get close to the fixed jaw, and at the same time, the materials are crushed or smashed, thus reaching the goal of crushing; when the movable jaw goes down, the angle between the toggle pate and the movable jaw is smaller, under the effect of the draw bar and the spring, the movable jaw moves always from the fixed jaw, and then the crushed materials will be discharged out from the lower mouth of the crushing chamber. With the continuous rotation of the electro motor, the movable jaw of the crusher will do periodic motion to crush and discharge the materials, thus realizing mass production.

Technical data

| Model |

Max.feeding

size (mm) |

Processing

capacity

(t/h) |

| PE-150×250 |

125 |

1-3 |

| PE-200×300 |

180 |

2-6 |

| PE-200×350 |

180 |

3-10 |

| PE-250×400 |

210 |

5-21 |

| PE-400×600 |

340 |

16-60 |

| PE-500×750 |

425 |

40-110 |

| PE-600×750 |

500 |

80-240 |

| PE-600×900 |

500 |

50-160 |

| PE-750×1060 |

630 |

110-320 |

| PE-800×1060 |

640 |

130-330 |

| PE-830×1060 |

650 |

150-336 |

| PE-870×1060 |

660 |

190-336 |

| PE-900×1060 |

685 |

230-390 |

| PE-900×1200 |

750 |

220-380 |

| PE-1000×1200 |

850 |

315-500 |

| PE-1200×1500 |

1020 |

400-800 |

| PE-1500×1800 |

1200 |

500-1000 |

| PEX-150×750 |

120 |

8-25 |

| PEX-250×750 |

210 |

13-35 |

| PEX-250×1000 |

210 |

16-52 |

| PEX-250×1200 |

210 |

20-61 |

| PEX-300×1300 |

250 |

16-105 |

30 seconds for connecting customer service

30 seconds for connecting customer service

30 minutes for getting technical answer

30 minutes for getting technical answer

24 hours for getting free solution plan

24 hours for getting free solution plan