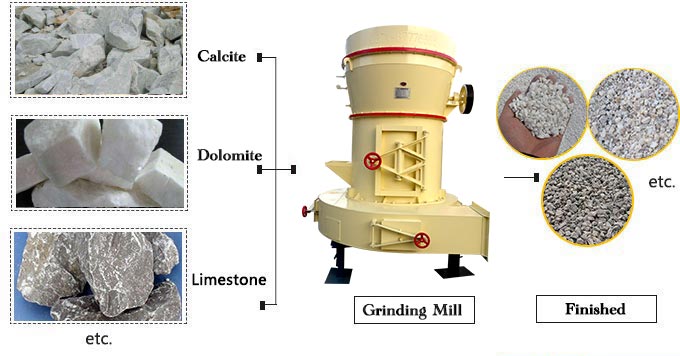

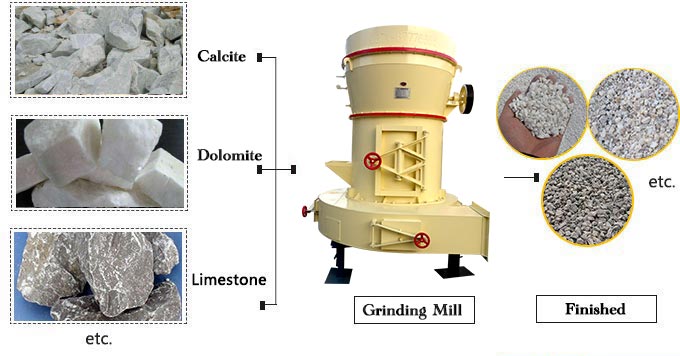

The Handling Materials and Application of Powder Grinding Mill:

Powder grinding mill is suitable for grinding non-flammable and non-explosive materials whose Moh’s hardness is below 9.3 and humidity less than 6% such as barite, limestone, ceramics and slag in mine, metallurgy, chemistry and building material industry and the granularity of the final products can be adjusted between 80 and 425 meshes. The machine can produce coarse powders of 30-80 mesh through the special device inside the machine.

The Performance Characteristics of Powder Grinding Mill:

1. This pulverizer has stereochemical structure, small coverage size and a production system can be independently formed from massive materials to final powders.

2. The fineness of the final powders is even and the through-screen rate is 99%.

3. The transmission device adopts sealed gear case and belt wheel with stable transmission and reliable operation.

1. The main parts use fine steel materials and the wear-resistant parts use high performance wear-resistant materials, so that the whole machine has high wear-resisting property and reliable operation.

2. The electrical system is centrally controlled and the maintenance is convenient.

Inside the powder grinding mill, there is a high pressure spring with 1000-1500 kilos of pressure on the cradle of the grinding roller. When this machine begins to work, the grinding roller rotates around the principal axis, and under the high pressure spring and centrifugal force, the grinding roller will roll to the grinding ring, and the pressure is 1.2 times higher than that of Raymond mill, so that the output is greatly improved. When the materials to be ground go into the grinding chamber, they are scooped up by the scraper knife and sent to the space between the grinding roller and the grinding ring for grinding, and the ground powders are brought to the analytical engine with the recirculating air of the blower, and the qualified fine powders flow into the cyclone powder collector with the air flow to become final products and the coarse powders will fall to the grinding mill for re-grinding.

Technical data

Parameter

Model |

Feeding

size(mm) |

Size of finished

product(mm) |

| High-strength97 |

≤25 |

0.173-0.033 |

| High-strength93 |

≤25 |

0.173-0.033 |

| High-strength92 |

≤25 |

0.173-0.033 |

| High-strength87 |

≤25 |

0.173-0.033 |

| High-strength76 |

≤20 |

0.173-0.033 |

| High-strength66 |

≤15 |

0.173-0.033 |

| High-strength62 |

≤15 |

0.173-0.033 |

| High-strength4119 |

≤25 |

0.173-0.044 |

| High-strength4525 |

≤30 |

0.173-0.044 |

Quick Way To Get Price

Note:For product inquiry or order requirements, Please fill the following form,

and we will contact you within one business day,

and all your information is kept confidential and is not shared with any third parties.

30 seconds for connecting customer service

30 seconds for connecting customer service

30 minutes for getting technical answer

30 minutes for getting technical answer

24 hours for getting free solution plan

24 hours for getting free solution plan