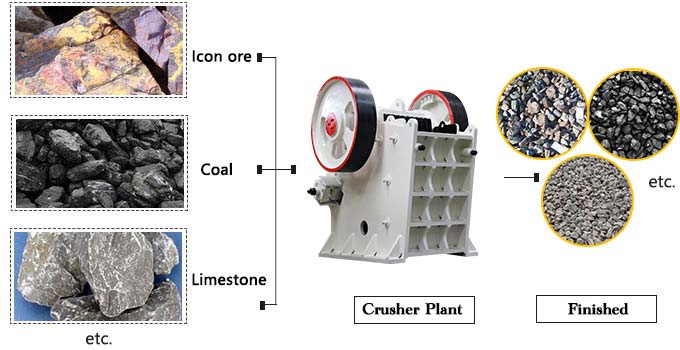

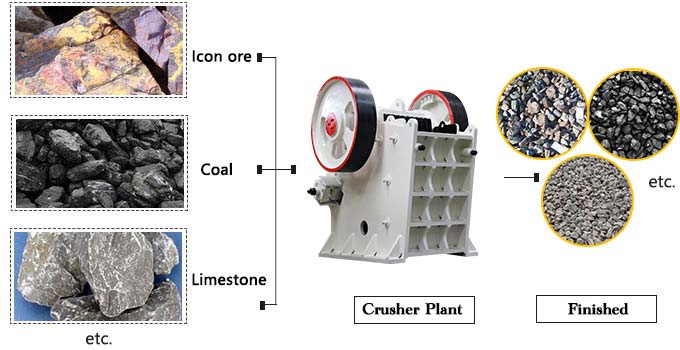

The Handling Materials of Crusher Plant:

Crusher plant can process some materials such as pebble, calcite, granite, quartz, concrete, dolomite, iron ore, limestone, iron ore, coal, construction waste, basalt, sandstone, rocks, ore, glass, cement clinker and some metal.

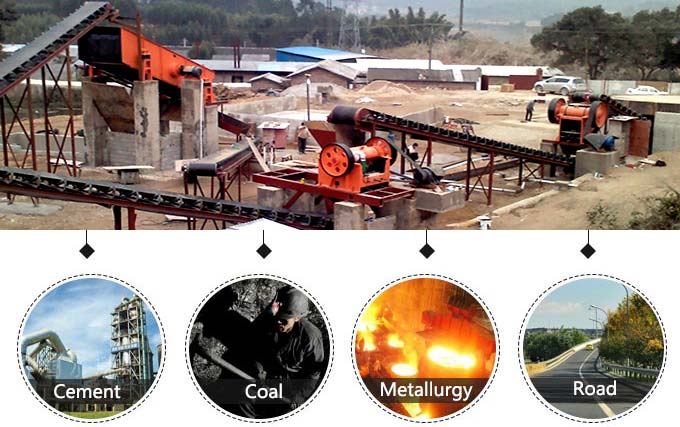

The Application and Features of Crusher Plant:

Crusher plant is ideally suitable for primary and secondary crushing, which is widely used in mining, metallurgy, construction, highway, railway, irrigation and chemical industries, and which has the features of high reduction ratio, even powder sizes, low power consumption and easy maintenance. The crushing strength of this crusher plant is up to 320 Mpa.

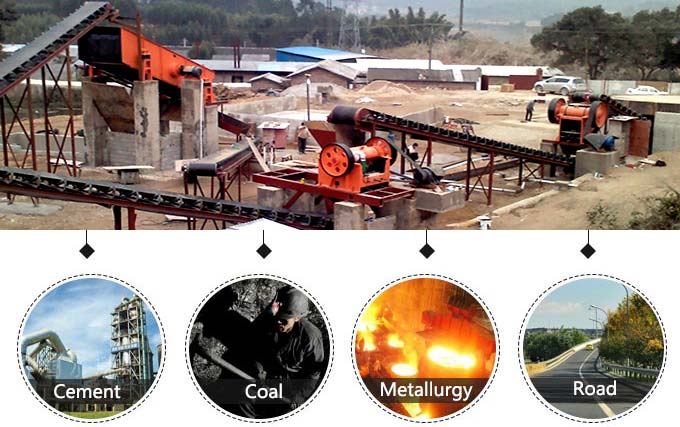

The Application and Features of Crusher Plant:

Crusher plant is ideally suitable for primary and secondary crushing, which is widely used in mining, metallurgy, construction, highway, railway, irrigation and chemical industries, and which has the features of high reduction ratio, even powder sizes, low power consumption and easy maintenance. The crushing strength of this crusher plant is up to 320 Mpa.

The Working Process of Crusher Plant:

The strip and strip pulley are driven by a motor, and the movable jaw moves up and down via eccentric shaft. The angle between fixed jaw and movable jaw becomes smaller when the movable jaw runs down, then the materials are crushed into pieces. The movable jaw board leaves the fixed jaw board under the action of pole and spring, and then the finished products come out from the crushing cavity.

Technical data

| Model |

Max.feeding

size (mm) |

Processing

capacity

(t/h) |

| PE-150×250 |

125 |

1-3 |

| PE-200×300 |

180 |

2-6 |

| PE-200×350 |

180 |

3-10 |

| PE-250×400 |

210 |

5-21 |

| PE-400×600 |

340 |

16-60 |

| PE-500×750 |

425 |

40-110 |

| PE-600×750 |

500 |

80-240 |

| PE-600×900 |

500 |

50-160 |

| PE-750×1060 |

630 |

110-320 |

| PE-800×1060 |

640 |

130-330 |

| PE-830×1060 |

650 |

150-336 |

| PE-870×1060 |

660 |

190-336 |

| PE-900×1060 |

685 |

230-390 |

| PE-900×1200 |

750 |

220-380 |

| PE-1000×1200 |

850 |

315-500 |

| PE-1200×1500 |

1020 |

400-800 |

| PE-1500×1800 |

1200 |

500-1000 |

| PEX-150×750 |

120 |

8-25 |

| PEX-250×750 |

210 |

13-35 |

| PEX-250×1000 |

210 |

16-52 |

| PEX-250×1200 |

210 |

20-61 |

| PEX-300×1300 |

250 |

16-105 |

30 seconds for connecting customer service

30 seconds for connecting customer service

30 minutes for getting technical answer

30 minutes for getting technical answer

24 hours for getting free solution plan

24 hours for getting free solution plan