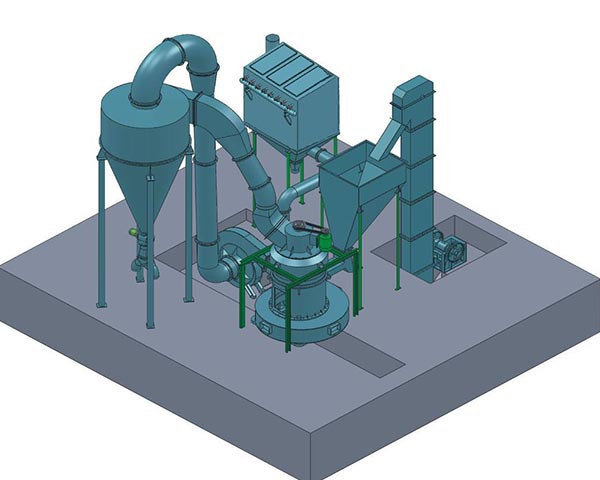

Product introduction: Superfine grinding mill is new type product with the international advanced technological level developed by our company by absorbing the domestic and overseas excellent technology and concept on the basis of the actual situation of customers and the experience of our researchers in the past 20 years.

Brief Introduction

Superfine grinding mill is one new type product with the international advanced technological level developed by our company by absorbing the domestic and overseas excellent technology and concept on the basis of the actual situation of customers and the experience of our researchers in the past 20 years. This machine can be used to process all kinds of non-explosive mineral materials with the mosh hardness below 9.3 and humidity below 7%, which is the perfect choice for the materials such as quartz, feldspar, calcite, limestone, talc, ceramics, marble, granite, dolomite, bauxite, iron ore, baritone, bentonite, coal gangue, coal and so on, and the fineness of finished products can be adjusted between 0.18mm-0.015mm (80 mesh - 800 mesh).

1. Spring-loaded device of high pressure spring can make the grinding pressure of roller increasing, production increasing and materials range wide.

2. Roller device adopts the most advanced multi-stage sealing including mechanical sealing and overlapping sealing, whose sealing performance is good, which can lower the maintenance cost and prolong the lifespan of equipment.

3. The core parts adopts high performance wear-resistant alloy materials, whose wearing resistant is high in order to reach cost-savings.

4. The improved turbine analysis machine adopts high-density blades, and then air resistance is being reduced, the fineness and production being increasing. The regulation of frequency analysis machine is more accurate, more energy saving, whose sorting efficiency is better and automation level is higher.

5. Taking some measures such as soft connection and processing of rubber mats can effectively reduce vibration, avoiding the influence of vibration in grinding chamber on analysis machine in order to improve the analysis fineness and lower the noise at the same time, which lastly improves the working place of workers.

The materials being crushed into small particles will be sent to the storage hopper by bucket elevator, and then being sent to the host at station by the electric vibrating feeder to be grounded. The grinder roller device, hanging on the plum frame, rotates around the center shaft in the host, and the grinding roller turns on its own axis at the same time. The grinder roller swings outwards and presses grinding rings under the action of centrifugal force. The grinding materials can be mashed and grounded under the action of grinding rollers. The air blower blows powders to the analytic engine to be analyzed in the grinding chamber, and the fineness of the materials will fall into the host to be grounded again, and the fineness meeting the specification will enter the whirlwind machine collecting with the airflow, and they will become the finished products after being collected and discharged through discharging port. The purified airflow will enter into the air blower through the pipeline on the upside of the whirlwind machine collector and grinding chamber. The dust cannot overflow, so it can protect the environment. Thanks to the moisture in the materials will be evaporated into gas, which flows through the pipeline and the feed inlet and increases the air volume in the cycle roads, and the increased air volume will be discharged after being purified by the bag-type dust collector.

Technical data

| Type |

Size of finished

product (mm) |

Shift output

of different

material

fineness (t/h) |

| HGM100 |

0.25-0.015 |

0.8-6 |

| HGM120 |

0.25-0.015 |

1.2-8 |

| HGM130 |

0.25-0.015 |

1.8-12 |

| HGM160 |

0.25-0.015 |

2.8-20 |

| HGM175 |

0.25-0.015 |

3.5-25 |

30 seconds for connecting customer service

30 seconds for connecting customer service

30 minutes for getting technical answer

30 minutes for getting technical answer

24 hours for getting free solution plan

24 hours for getting free solution plan