The Handling Materials and Application of Sand Dryer:

Sand Dryer has strong adaptability, processing capability, which can process coal washing, fertilize, ore, sand, clay, kaolin, sugar, and which can be used in metallurgy, building materials, food, light industry, chemical industry, coal, medicine and mining industries.

The Inner Structure and Advantages of Sand Dryer:

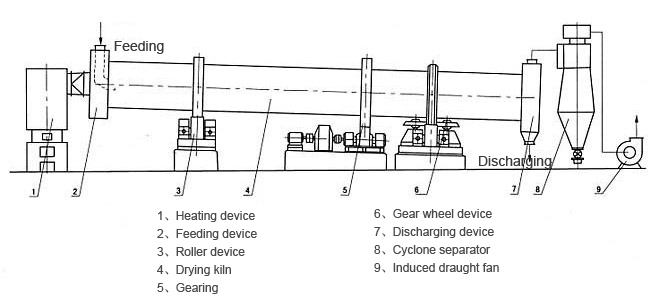

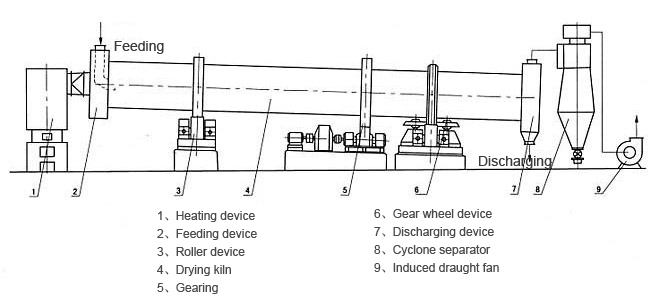

The sand dryer mainly consists of rotor, shed plate, transmission device, support device, seal ring, and other spare parts. The rotary dryer has the advantages of reasonable structure, excellent manufacture, high output, low energy consumption, convenient operation and so on.

1. Sand dryer is made of wear-resistant manganese plate, 3-4 times wear-resistant than ordinary steel plate. Raw material is with moisture within 15%, and moisture of dried material is lower 0.5-1%. Compared to traditional single cylinder drying machine, its thermal efficiency can be improved about 40% or more.

2. The outside cylinder temperature is lower than 60 degrees, and the waste gas temperature is lower than 120 degrees, and the service life of dust collector bag is more than twice of that of other collector. Coal consumption is one-third of the single cylinder dryer, save electricity 40%, with per ton consumption of standard coal lower than 9 kg.

Sand will be fed into the hopper through belt conveyor and bucket elevator, and then be fed into the end hopper through feeding machine or pipes. The inclination of feeding pipe should be larger than natural inclination of materials, for sand smoothly entering into the dryer. Dryer drum is a slightly inclined rotating cylinder with horizontal lines. Materials are fed from the higher end, while heat medium enters from low-end, forming counter-current contact with materials. Heat medium flowing into the cylinder together with material is available. As the rotation of the cylinder, materials run to the end of the sand dryer under gravity. Wet material, in the course of the cylinder moving forward, directly or indirectly get heat from medium heat, for drying wet material, and then discharged through the spiral conveyor or belt conveyor installed at the end of discharging port. Sand dryer is equipped with lifting board on the cylinder wall, and the lifting board plays the role of lifting and falling down materials, increasing the contact surface between material and air flow, so as to improve the drying rate. Heat medium is generally divided into hot air, flue gas and others. Generally, heat medium after being dried needs to be cleaned the materials filled in gas by cyclone dust collector. If you need to further reduce exhaust dust content, pass through bag filter or wet dust collector before discharging it.

Technical data

| Item |

φ2.0×6m |

φ2.5×6.5m |

φ2.7×7m |

φ3×7m |

φ3.2×7m |

φ3.6×8m |

φ4.2×8.5m |

| Diameter of outer cylinder (m) |

2.0 |

2.5 |

2.7 |

3 |

3.2 |

3.6 |

4.2 |

| Length of outer cylinder (m) |

6 |

6.5 |

7 |

7 |

7 |

8 |

8.5 |

| Cylinder volume (m³) |

18.84 |

31.89 |

40.5 |

49.46 |

56.26 |

81.38 |

118 |

| Rotating speed of cylinder (rpm) |

3-10 |

3-10 |

3-10 |

3-10 |

3-10 |

3-10 |

3-10 |

| retention time of materials (min) |

12-30 |

12-30 |

12-30 |

12-30 |

12-30 |

12-30 |

12-30 |

| Initial moisture of materials (%) |

6-25 |

6-25 |

6-25 |

6-25 |

6-25 |

6-25 |

6-25 |

| Final moisture of materials (%) |

≤1 |

≤1 |

≤1 |

≤1 |

≤1 |

≤1 |

≤1 |

| Highest intake air temperature ( ℃ ) |

750-900 ℃ |

750-900 ℃ |

750-900 ℃ |

750-900 ℃ |

750-900 ℃ |

750-900 ℃ |

750-900 ℃ |

| Production capacity (T/H) |

Slag |

20-25 |

25-30 |

30-35 |

35-10 |

40-45 |

50-65 |

70-85 |

| Coal ash |

10-17 |

17-21 |

20-25 |

23-27 |

25-30 |

30-45 |

45-63 |

| Yellow sand |

20-27 |

25-40 |

27-45 |

30-45 |

35-50 |

55-75 |

75-99 |

| Motor type |

Yr160m-4 |

Yr132m-4E |

Yr160m-4 |

Yr160m-4 |

Yr132m-5E |

Yr160m-4E |

Yr160m-4E |

| Motor power (kw) |

7.5×2 |

11×2 |

7.5×4 |

7.5×4 |

11×4 |

15×4 |

18.5×4 |

| Reducer type |

XWD-6 |

XWD-6 |

XWD-6 |

XWD-6 |

XWD-6 |

XWD-8 |

XWD-8 |

| Velocity ratio of reducer (I) |

17-29 |

17-29 |

17-29 |

17-29 |

17-29 |

17-29 |

17-29 |

30 seconds for connecting customer service

30 seconds for connecting customer service

30 minutes for getting technical answer

30 minutes for getting technical answer

24 hours for getting free solution plan

24 hours for getting free solution plan