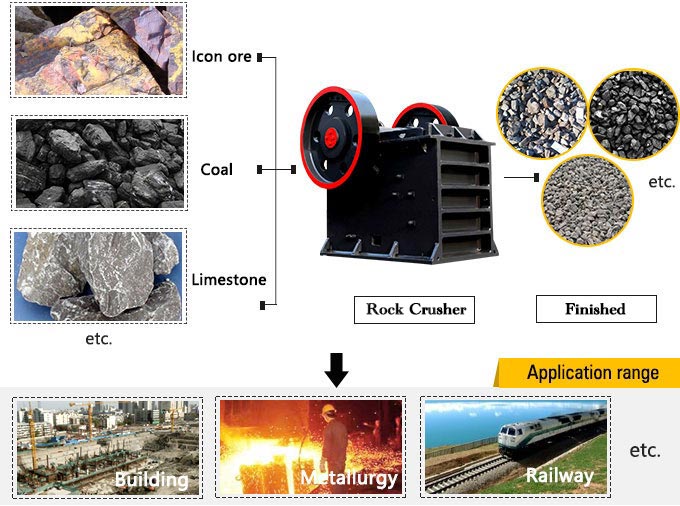

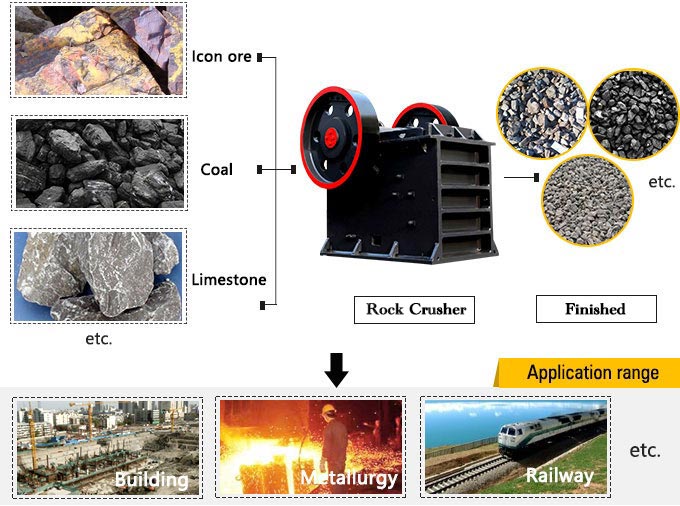

The Handling Materials and Application of Rock Crusher:

Rock crusher can widely be used in some fields such as highways, crushing project, bridge and artificial sand making. The materials of rock crusher are pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, iron ore, coal gangue, construction waste, ferrosilicon, basalt, sandstone, rocks, ore, glass, cement clinker and some metal.

The Advantages and Benefits of Rock Crusher:

1. Small volume, light wight, higher processing capacity and lower production cost.

2. Energy saving and higher working efficiency.

3. Big crushing ratio, simple crushing production line.

4. Uniform and cubic finished products.

The working manner of this series crushing machine is dynamic extrusion type, and its working principle goes like this: the electro motor drives the belt and belt wheel to make the movable jaw to move up and down through the eccentric shaft, and then movable jaw goes up, the angle between the toggle pate and the movable jaw is bigger, thus pushing the movable jaw to get close to the fixed jaw, and at the same time, the materials are crushed or smashed, thus reaching the goal of crushing; when the movable jaw goes down, the angle between the toggle pate and the movable jaw is smaller, under the effect of the draw bar and the spring, the movable jaw moves always from the fixed jaw, and then the crushed materials will be discharged out from the lower mouth of the crushing chamber. With the continuous rotation of the electro motor, the movable jaw of the crusher will do periodic motion to crush and discharge the materials, thus realizing mass production.

Technical data

| Model |

Max.feeding

size (mm) |

Processing

capacity

(t/h) |

| PE-150×250 |

125 |

1-3 |

| PE-200×300 |

180 |

2-6 |

| PE-200×350 |

180 |

3-10 |

| PE-250×400 |

210 |

5-21 |

| PE-400×600 |

340 |

16-60 |

| PE-500×750 |

425 |

40-110 |

| PE-600×750 |

500 |

80-240 |

| PE-600×900 |

500 |

50-160 |

| PE-750×1060 |

630 |

110-320 |

| PE-800×1060 |

640 |

130-330 |

| PE-830×1060 |

650 |

150-336 |

| PE-870×1060 |

660 |

190-336 |

| PE-900×1060 |

685 |

230-390 |

| PE-900×1200 |

750 |

220-380 |

| PE-1000×1200 |

850 |

315-500 |

| PE-1200×1500 |

1020 |

400-800 |

| PE-1500×1800 |

1200 |

500-1000 |

| PEX-150×750 |

120 |

8-25 |

| PEX-250×750 |

210 |

13-35 |

| PEX-250×1000 |

210 |

16-52 |

| PEX-250×1200 |

210 |

20-61 |

| PEX-300×1300 |

250 |

16-105 |

30 seconds for connecting customer service

30 seconds for connecting customer service

30 minutes for getting technical answer

30 minutes for getting technical answer

24 hours for getting free solution plan

24 hours for getting free solution plan